LEARN MORE ABOUT ANDRONACO INDUSTRIES

PIPING PRODUCTS

EXPANSION JOINTS

STRAINERS

HOSES

SIGHT FLOW INDICATORS

SAMPLING SYSTEMS

DIAPHRAGM PUMPS

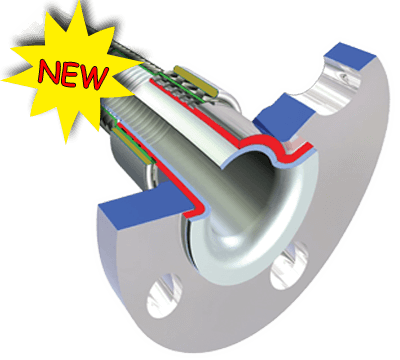

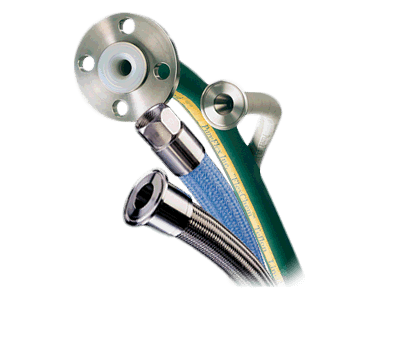

Introducing Nexus™, the smooth bore convoluted hose from PureFlex.

Introducing Nexus™, the smooth bore convoluted hose from PureFlex.