860 Series Overview

The Strongest, Lightest, most Chemically Resistant Valve in the World

- Corrosion Resistant

- Strong as Steel

- ½ the weight of Steel

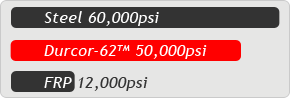

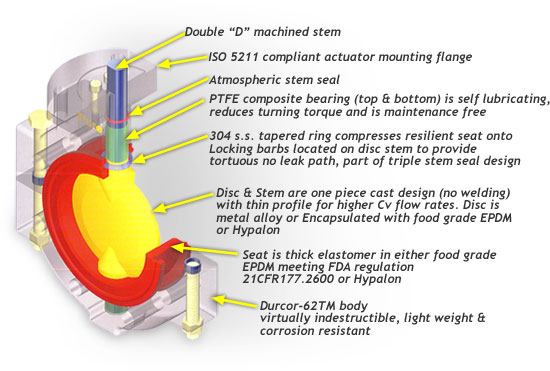

The 860 Series valve body is manufactured from Durcor®, PureFlex's proprietary advanced fiber-reinforced composite. Durcor® has tensile and compressive strengths that rival steel along with outstanding impact resistance that is unmatched in the industry. Its reinforcing fibers are long and interlocked; this interlocked reinforcement system transfers loads throughout the fiber matrix, making the 860 Series valve body virtually indestructible. The strength of Durcor® enables the 860 Series valve to maintain ANSI face-to-face dimensions, be direct threaded for lug design, and allows it to be installed in any type of piping system without the need for special considerations. Durcor® excels in temperatures from -60ºF to +250ºF and has only .001" of thermal expansion across its full temperature range.

Composite Valve Body Durcor 62™

Tensile Strength Comparison

The Durcor® vinyl ester resin backbone provides excellent protection when exposed to aggressive chemicals and hostile atmospheres such as acid sprays, bleach, salt water, and high chlorides. The 860 Series valve body outperforms ductile iron valves not only in corrosive environments but non-corrosive as well. Its lightweight advantage reduces the need for heavier support structures for hanging, eliminates the need for extra equipment and personnel for valve installation, and reduces pipe strain once installed. The 860 Series “valve body” is so dependable and maintenance-free that we offer the industry's first 5 year warranty against failure. Contact PureFlex or your local distributor for details.

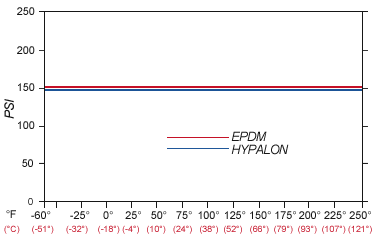

PureFlex 860 Series valves take resilient seated butterfly valve technology to the next generation of reliability. The valve is bubble tight at full rated pressure of 150psi, has triple stem seals for unmatched leak free dependability, and it can operate at temperatures between -60°F to +250°F (consult factory for higher temperature applications). The 860 fiber-reinforced vinyl ester valve body has a zero corrosion rate, the strength of steel with only ½ the weight, and is virtually indestructible. The 860 Series is used for shut-off, throttling and transfer of many corrosive and erosive fluids, and has the purity required for ultra-pure and food applications.

Technical Data

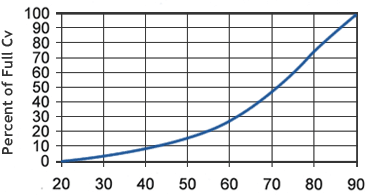

Cv at Disc Angle of Rotation

| Disc Rotation (Degrees) | |

|---|---|

| refer to chart above | |

| Disc Position (degrees) | Percent of Total Cv |

| 20 | 0 |

| 30 | 3 |

| 40 | 9.1 |

| 50 | 16.3 |

| 60 | 27.4 |

| 70 | 47 |

| 80 | 74.5 |

| 90 | 100 |

| Sizing Torques | |

|---|---|

| Valve Size | Max. Differential Pressure |

| 2" | 152 in.- lbs. |

| 3" | 218 in.- lbs. |

| 4" | 350 in.- lbs. |

| 6" | 794 in.- lbs. |

| 8" | 1210 in.- lbs. |

| 10" | 2360 in.- lbs. |

| 12" | 3617 in.- lbs. |

Pressure / Temperature

| Cv DATA | |

|---|---|

| refer to chart above | |

| Valve Size | Full Open Cv |

| 2" | 112 |

| 3" | 334 |

| 4" | 570 |

| 6" | 1415 |

| 8" | 3110 |

| 10" | 5223 |

| 12" | 7944 |

Parts List & Materials

| 860 Series Valve Parts List | |||

|---|---|---|---|

| * = Raw material compliant with requirements set forth in FDA reg. 21 CFR 177.2600 Viton® = Registered trademark of Dupont Dow Elastomers |

|||

| Item | Description | Standard Material | Qty. |

| 1a & 1b | Body | Durcor® | 1 |

| 2 | omitted | ||

| 3 | Nut | Gr. 2H ASTM A194-PTFE Coated | 2 |

| 4 | Stem Extension (4" & 6" Sizes Only) | CF8M Stainless Steel | 1 |

| 5 | Disc | EPDM \ Nickel Plated DCI | 1 |

| 6 | Seat | *Food Grade EPDM (ASTM D2000 #MICA714Z) | 1 |

| 7 | Taper Ring | 304 Stainless Steel | 2 |

| 8 | Bearing | PTFE-Composite | 2 |

| 9 | Atmospheric Seal | Viton® (FKM) | 1 |

| 10 | Socket Head Cap Screw | Gr. B7 ASTM A193 Zinc Plated | 4 |

| 11 | ISO Mounting Flange | Durcor® | 1 |

| 12 | Hex Head Cap Screw | Gr. B7 ASTM A193 Zinc Plated | 2 |

| Valve Options | |

|---|---|

| Hastelloy® is a registered trademark of Haynes International, Inc. Hypalon® is a registered trademark of Dupont Dow Elastomers. |

|

| Item | Optional Material |

| 10 | Gr. B840 ASTM A193 Stainless Steel |

| Hastelloy® C276 ASTM B574 | |

| 6 | Viton® (FKM) |

| Hypalon® (CSM) | |

| 5 | UHMWPE \ Stainless Steel |

| CF8M Stainless Steel | |

| CW6M (Hastelloy® C276) ASTM A494 | |

| Titanium Gr. C-2 ASTM B367 | |

| 12 | Gr. B840 ASTM A193 Stainless Steel |

| Hastelloy® C276 ASTM B574 | |

| 4 | CW6M (Hastelloy® C276) ASTM A494 |

| Titanium Gr. C-2 ASTM B367 | |

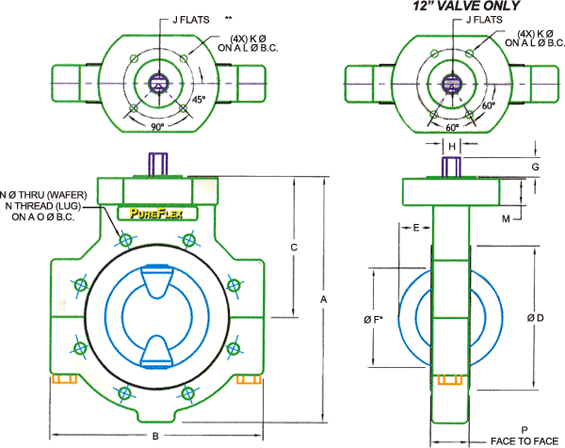

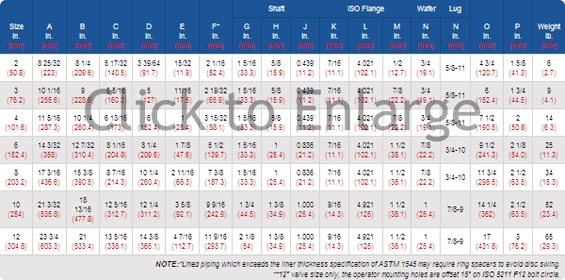

Dimensions & Weights

| Wafer and Lug Valves with Gear | ||||||

|---|---|---|---|---|---|---|

| Size in. (mm) |

A in. (mm) |

B in. (mm) |

C in. (mm) |

D in. (mm) |

E in. (mm) |

F in. (mm) |

| 2 — 4 (76.2) (152.4) |

6 1/4 (158.7) |

5 (127) |

2 37/64 (65.5) |

1 7/64 (28.2) |

2 1/16 (52.3) |

6 (152.4) |

| 6 — 8 (152.4) (203.2) |

6 3/4 (171.4) |

5 (127) |

2 37/64 (65.5) |

1 7/64 (28.2) |

2 1/16 (52.3) |

8 (203.2) |

| 10 — 12 (254)(304.8) |

7 1/4 (184.1) |

6 23/32 (170.7) |

2 63/64 (75.7) |

1 3/8 (34.8) |

2 1/2 (63.5) |

12 (304.8) |

| Fasteners for Installation of Lug Bodies | |||||||

|---|---|---|---|---|---|---|---|

| Valve Size | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| Number of Fasteners | 8 | 8 | 16 | 16 | 16 | 24 | 24 |

| Thread Call-out | 5/8 - 11 UNC | 3/4 - 10 UNC | 7/8 - 9 UNC | ||||

| "A" Length of Fastener | 1-1/2 | 1-3/4 | 1-3/4 | 2 | 2-1/4 | 2-1/2 | 2-1/2 |

| Fasteners for Installation of Wafer Bodies | |||||||

|---|---|---|---|---|---|---|---|

| Valve Size | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| Number of Fasteners | 4 | 4 | 8 | 8 | 8 | 12 | 12 |

| Thread Call-out | 5/8 - 11 UNC | 3/4 - 10 UNC | 7/8 - 9 UNC | ||||

| "B" Length of Fastener | 5 | 5-1/2 | 5-3/4 | 6-1/2 | 6-3/4 | 7-3/4 | 8-1/4 |