800 Series Overview

The Strongest, Lightest, most Chemically Resistant Valve in the World

- Corrosion Resistant

- Strong as Steel

- ½ the weight of Steel

The PureFlex 800 Series fully lined composite valve is manufactured to be corrosion resistant inside and out in hostile services. The valve has the strength of steel with ½ the weight and is 10× more impact resistant than standard FRP. They are used for shut-off and throttling of most known corrosive fluids, and have the purity required for ultra-pure applications. The 800 Series can be used for end of the line service and is bubble tight at full rated pressure of 150psi, has triple stem seals and can operate at temperatures of -60ºF to +250ºF.

Composite Valve Body Durcor®

The 800 Series valve body is manufactured from Durcor®, PureFlex's proprietary advanced fiber reinforced composite. Durcor® reinforcing fibers are long and interlocked; this interlocked reinforcement system transfers loads throughout the fiber matrix making the 800 series valve body virtually indestructible. It has tensile and compressive strengths that rival steel along with outstanding impact resistance that is unmatched in the industry.The strength of Durcor® enables the 800 series valve to maintain ASME face to face dimensions, be direct threaded for lug design and allows it to be installed in any type of piping system without the need for special considerations. Durcor® excels in temperatures from -60°F to +250°F and has only .001” of thermal expansions across its full temperature range.

The 800 Series valve body is manufactured from Durcor®, PureFlex's proprietary advanced fiber reinforced composite. Durcor® reinforcing fibers are long and interlocked; this interlocked reinforcement system transfers loads throughout the fiber matrix making the 800 series valve body virtually indestructible. It has tensile and compressive strengths that rival steel along with outstanding impact resistance that is unmatched in the industry.The strength of Durcor® enables the 800 series valve to maintain ASME face to face dimensions, be direct threaded for lug design and allows it to be installed in any type of piping system without the need for special considerations. Durcor® excels in temperatures from -60°F to +250°F and has only .001” of thermal expansions across its full temperature range.

PureFlex 860 Series valves take resilient seated butterfly valve technology to the next generation in reliability. The valve is bubble tight at full rated pressure of 150psi, has triple stem seals for unmatched leak free dependability, and it can operate at temperatures between -60°F to +250°F (consult factory for higher temperature applications). The 860 fiber-reinforced vinyl ester valve body has a zero corrosion rate, the strength of steel with only ½ the weight, and is virtually indestructible. The 860 Series is used for shut-off, throttling, and the transfer of many corrosive and erosive fluids, and has the purity required for ultra-pure and food applications.

PureFlex 860 Series valves take resilient seated butterfly valve technology to the next generation in reliability. The valve is bubble tight at full rated pressure of 150psi, has triple stem seals for unmatched leak free dependability, and it can operate at temperatures between -60°F to +250°F (consult factory for higher temperature applications). The 860 fiber-reinforced vinyl ester valve body has a zero corrosion rate, the strength of steel with only ½ the weight, and is virtually indestructible. The 860 Series is used for shut-off, throttling, and the transfer of many corrosive and erosive fluids, and has the purity required for ultra-pure and food applications.

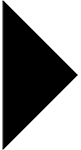

Features

- Composite Durcor® valve body is light weight, provides maximum external corrosion protection, tensile and impact resistance.

- PTFE seat is .125" nominal thickness and is recessed into body, seat is energized by one piece non-wetted elastomer providing bubble tight sealing.

- Once piece 316 S.S. disc & Stem provides high Cv valve. blow-out protection and has double "D" shaft drive, can be lined with PFA / UHMWPE or unlined.

- Mounting Flange is ISO 5211 compliant.

- NPT connections (optional) for purge or leak detection, inert gas pad or sealing lubrication port.

- PTFE composite bearing (top & bottom) is self-lubricating, reduces friction and is maintenance free.

- Triple stem seals top and bottom.

- 304 S.S. coil springs keep preload on stem seal and taper ring.

- 304 S.S. tapered ring compresses energized PTFE liner onto locking barbs, creates tortuous no leak path.

- Locking barbs molded or machined onto disc stem.

- Stem seal is created through an interference fit as the stem is passed through the body liner.

- Primary seal is achieved at the disc hub and liner (ball & socket) through preloaded force.

- Bottom heavy hex fasteners eliminates exposure to leaks from overhead equipment, PTFE coated B7 standard. Other materials available.

- Flanged Wafer or Lug design with composite threads 250ft. pound pull - out strength. Alloy inserts also available.

Liners & Discs

Maximum Abrasion Resistance Against Erosive Services

Ultra high Molecular Weight Polyethylene is a tough abrasion-resistant polymer perfectly suited for severe erosive services while providing good chemical resistance. UHMWPE will consistently outperform rubber-lined or plastic valves in fluids containing abrasive particles with or without corrosive media present at temperatures of -20°F to +200°F. PureFlex 800 Series valves with UHMWPE are ½ the weight of metal lined valves and provide outstanding service life in pulp and paper processing, mining and metal refining, power plants, pollution abatement, and chemical industries. Typical services include:

- Sodium Chloride Brine

- Titanium Dioxide slurry

- Iron Ore tailings

- Zinc Sulfate slurry

- White liquor

- Green liquor

- Lime mud

- Lime slurry

- Fly ash

Maximum Chemical Resistance Against Corrosive Services

PTFE (Polytetrafluoroethylene) and PFA (Perfluoroalkoxy) are fluoropolymers that provide outstanding chemical and temperature resistance from -60°F to +250°F. The fluoropolymers non-stick properties aid to eliminate build-up of deposits on valve seat and disc that could possibly affect valve performance. PureFlex 800 Series valves lined with PTFE / PFA are unequalled for severe chemical services and will resist the attacks of:

- All Acids

- All Solvents

- All Bleach solutions

- All Caustics

- All Peroxides

- All Phenols

- All Organic Chlorides & Sulfates

- All Inorganic Chlorides & Sulfates

Technical Data

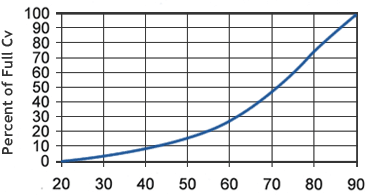

Cv at Disc Angle of Rotation

| Disc Rotation (Degrees) | |

|---|---|

| Refer to chart above | |

| Disc Position (degrees) | Percent of Total Cv |

| 20 | 0 |

| 30 | 3 |

| 40 | 9.1 |

| 50 | 16.3 |

| 60 | 27.4 |

| 70 | 47 |

| 80 | 74.5 |

| 90 | 100 |

| Sizing Torques - Clean Clear Fluids | ||

|---|---|---|

| Valve Size | Max. Differential Pressure | |

| PTFE | UHMWPE | |

| 2" | 275 in.- lbs. | 405 in.- lbs. |

| 3" | 380 in.- lbs. | 463 in.- lbs. |

| 4" | 570 in.- lbs. | 2,300 in.- lbs. |

| 6" | 1250 in.- lbs. | 3660 in.- lbs. |

| 8" | 1660 in.- lbs. | 4116 in.- lbs. |

| 10" | 3600 in.- lbs. | 6915 in.- lbs. |

| 12" | 4800 in.- lbs. | 8102 in.- lbs. |

| Note: For slurries, add 35% to above values | ||

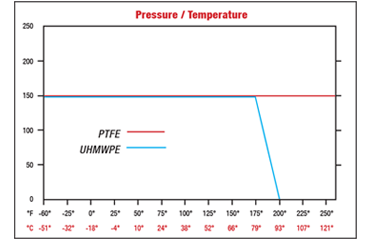

Pressure / Temperature

| Cv DATA | |

|---|---|

| Refer to chart above | |

| Valve Size | Full Open Cv |

| 2" | 112 |

| 3" | 334 |

| 4" | 570 |

| 6" | 1415 |

| 8" | 3110 |

| 10" | 5223 |

| 12" | 7944 |

Materials

| 800 Series Valve Parts List | |||

|---|---|---|---|

| Item | Description | Standard Material | Qty. |

| 1 | Upper Body | Durcor® | 1 |

| 2 | Lower Body | Durcor® | 1 |

| 3 | Atmospheric Seal | Viton® ( FKM ) | 1 |

| 4 | Socket Head Cap Screw | Gr. B7 ASTM A193-PTFE Coated | 4 |

| 5 | ISO Mounting Flange | Durcor® | 1 |

| 6 | Bearing | PTFE-Composite | 2 |

| 7 | Coil Spring | 304 Stainless Steel | 2 |

| 8 | Taper Ring | 304 Stainless Steel | 2 |

| 9 | Seat Energizer | Silicone | 1 |

| 10 | Seat | PTFE | 1 |

| 11 | Disc | PFA \ ENC DCI | 1 |

| 12 | Stem Extension (4" & 6" Sizes Only) | Gr. B7 ASTM A193-PTFE | 1 |

| 13 | Hex Head Cap Screw | CF8M Stainless Steel | 2 |

| Valve Options | |

|---|---|

| Item | Optional Material |

| 4 | Gr. B840 ASTM A193 Stainless Steel |

| Hastelloy® C276 ASTM B574 | |

| 9 | Viton® |

| 10 | UHMWPE |

| TFM \ NXT PTFE | |

| 11 | UHMWPE \ Stainless Steel |

| CF8M Stainless Steel | |

| CW6M (Hastelloy® C276) ASTM A494 | |

| Titanium Gr. C-2 ASTM B367 | |

| 12 | Gr. B840 ASTM A193 Stainless Steel |

| Hastelloy® C276 ASTM B574 | |

| 13 | CW6M (Hastelloy® C276) ASTM A494 |

| Titanium Gr. C-2 ASTM B367 | |

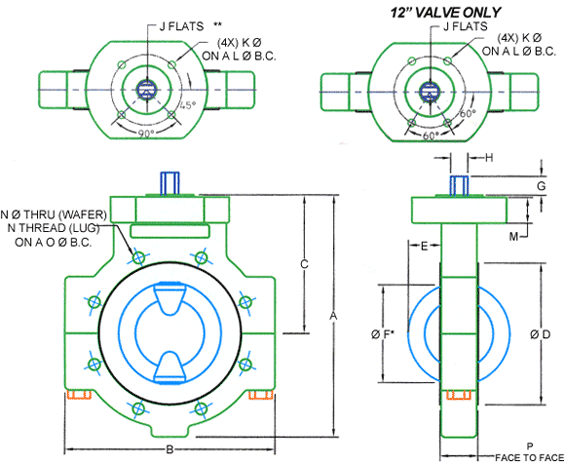

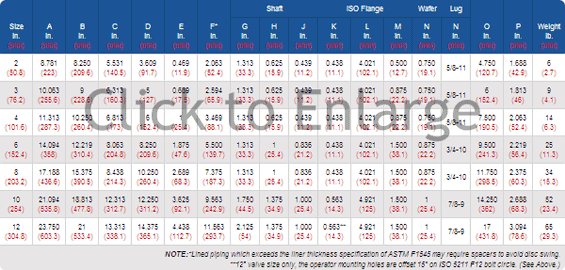

Dimensions & Weights

| Wafer and Lug Valves with Gear | ||||||

|---|---|---|---|---|---|---|

| Size in. (mm) |

A in. (mm) |

B in. (mm) |

C in. (mm) |

D in. (mm) |

E in. (mm) |

F in. (mm) |

| 2 — 4 (50.8)(101.6) |

6.250 (158.7) |

5 (127) |

2.578 (65.5) |

1.109 (28.2) |

2.063 (52.3) |

6 (152.4) |

| 6 — 8 (152.4)(203.2) |

6.750 (171.4) |

5 (127) |

2.578 (65.5) |

1.109 (28.2) |

2.063 (52.3) |

8 (203.2) |

| 10 — 12 (254)(304.8) |

7.250 (184.1) |

6.719 (170.7) |

2.984 (75.7) |

1.375 (34.8) |

2.500 (63.5) |

12 (304.8) |

| Fasteners for Installation of Lug Bodies | |||||||

|---|---|---|---|---|---|---|---|

| Valve Size | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| Number of Fasteners | 8 | 8 | 16 | 16 | 16 | 24 | 24 |

| Thread Call-out | 5/8 - 11 UNC | 3/4 - 10 UNC | 7/8 - 9 UNC | ||||

| "A" Length of Fastener | 1-1/2 | 1-3/4 | 1-3/4 | 2 | 2-1/4 | 2-1/2 | 2-1/2 |

| Fasteners for Installation of Wafer Bodies | |||||||

|---|---|---|---|---|---|---|---|

| Valve Size | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| Number of Fasteners | 4 | 4 | 8 | 8 | 8 | 12 | 12 |

| Thread Call-out | 5/8 - 11 UNC | 3/4 - 10 UNC | 7/8 - 9 UNC | ||||

| "B" Length of Fastener | 5 | 5-1/2 | 5-3/4 | 6-1/2 | 6-3/4 | 7-3/4 | 8-1/4 |