Overview

Ultra-Flexible Convoluted PTFE Hose for Heavy Duty Applications

- Corrosion Resistant

- Cleanable

- Flexible

UltraFlex™ heavy duty hose is made with the thickest seamless PTFE liner in the industry and offers the largest size range (1/2" - 6") which makes it ideal for nearly all demanding high purity and chemical applications. The open pitch spiral convolutions facilitate cleaning because they're self-draining, and the tight bend radius of UltraFlex hose is perfect for space-constrained locations. To ensure continuous fluid contact with PTFE throughout the hose assembly, the PTFE liner can be cuffed and flared through for a continuous fluid conduit.

UltraFlex™ Advantages

- Corrosion Resistant - PTFE is fully resistant to the broadest range of industrial chemicals and has a zero corrosion rate with lower life cycle costs.

- Cleanable - Non-Stick, low porosity tube is self cleaning and does not trap bacteria and can be cleaned with steam, detergents, caustics or solvents.

- Sanitary – FDA-approved materials meet or exceed Pharmacopoeia Class VI and 3A standards.

- Compatible - Will not contaminate or impart taste, color, or odor to any media.

- Flexible - Ultra flexible engineered design that resists cracking and stress corroding.

- Durable - Engineered for extended use in hostile environments involving severe chemical, thermal, and mechanical stresses. Does not suffer from aging or ernbrittlement like rubber, even with extreme thermal cycling.

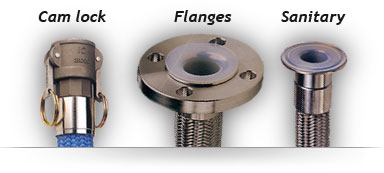

Flared-Thru Fittings

UltraFlex™ thick PTFE liner can be passed through the end fitting and flared radially outward against the sealing face to provide a continuous PTFE fluid conduit.

| Temperature Range | |||||||

|---|---|---|---|---|---|---|---|

| Operating pressure ratings are one-fourth the minimum burst pressure at (+)70°F (21°C) Pressure and vacuum ratings are based at (+)70°F (21°C) ** 3" is available for full vacuum applications - consult factory |

|||||||

| Stainless braid and bare hose temperature range: (-)65°F (-54°C) to (+)450°F (+232°C) Polypropylene braid temperature range: (-)20°F (-29°C) to (+)250°F (+121°C) |

|||||||

| I.D. Nominal (inch) |

Operating Pressure (psi) | Minimum Bend Radius (inch) |

Vacuum Rating (in-Hg) |

Weight Per Foot (lbs.) |

|||

| S.S. Braid |

Polypro Braid |

Bare Hose |

|||||

| 1/2" | 400 | 400 | 40 | 1.75 | 29.9 | 0.20 | |

| 3/4" | 400 | 400 | 30 | 2.25 | 29.9 | 0.35 | |

| 1" | 400 | 400 | 30 | 2.50 | 29.9 | 0.50 | |

| 1-1/4" | 325 | 275 | 20 | 3.00 | 29.9 | 0.70 | |

| 1-1/2" | 325 | 250 | 20 | 3.25 | 29.9 | 0.80 | |

| 2" | 250 | 225 | 15 | 5.25 | 29.9 | 0.95 | |

| 2-1/2" | 250 | 200 | 15 | 8.50 | 29.9 | 1.50 | |

| **3" | 175 | 175 | 15 | 9.50 | 24.0 | 1.79 | |

| 4" | 150 | 150 | 15 | 11.95 | 20.0 | 2.25 | |

| 6" | 75 | 50 | 5 | 15.50 | 15.0 | 3.50 | |

Hose Options

Hose Cover Options

-

Scuff Sleeve

Protects hose exterior from damage when dragged over rough surfaces -

Fire Sleeve

Protects hose from extreme exterior temperatures. Can be used as insulation and protects personnel from extreme interior temperatures -

Polyolefin

Provides a smooth, cleanable covering over braided hose. Many colors available -

Armor Guard

Protects hose from kinking by not allowing it to exceed its bend radius -

Spring Guard

Provides kink resistance and protects hose from damage when dragged over rough surfaces -

HDPE

Provides kink and wear protection during rough handling. Available in (8) colors for color coding and is the only protective cover that can be installed on an existing assembly

Electrically Heated Option

UltraFlex™ Spiral Vent Tubing

UltraFlex™ heavy wall PTFE makes it ideal for vent tubing or flanged hose assemblies where line pressures are relatively low. UltraFlex Spiral Vent Tubing assemblies provide excellent flexibility, are light weight and have superior chemical resistance. Available in sizes 1/2" to 6" with cuffed, flanged or a variety of other end connections and materials.

Durcor® Composite Flanges

- Strong as Steel

- 1/4 The Weight of Stainless Steel

- Class 150 Rated

- ASME B16.5 Class 150 Drilling

- (-)60°F to (+)300°F

- Lower Cost Then 316S.S.

- Lower Transportation cost

- Lower Installed Cost

- Lower Life Cycle Cost

- Zero Corrosion Rate

- 5 Year Warranty